Polishing Equipment

This specialized particle polishing machine offers nanoscale surface treatment for workpieces. Powered by compressed air, it generates a high-speed jet to spray elastic abrasive materials onto workpiece surfaces. This process subtly enhances surface cleanliness and roughness. With its ultra-fine abrasive particles, the machine can process complex surfaces, including narrow grooves, blind holes, and edges, and can handle components made from various materials by using tailored abrasives. It is widely applied in fields such as micro-hole deburring, mold polishing, tool passivation, and roughness improvement of components.

3D polishing machine, Irregular part polishing machine, Flow rate polishing machine

This device features pulse flow polishing technology, enabling advanced surface treatment of workpieces by combining circulating abrasives with rotating workpieces. It integrates multiple processes, such as deburring, smoothing, and polishing, into a single operation. This targeted approach ensures excellent surface quality for challenging flat and concave surfaces. The machine is versatile and applicable across industries with high surface treatment requirements.

This machine is specifically designed for high-speed polishing of micro-holes smaller than 0.5 millimeters. It utilizes a liquid work mechanism to efficiently polish the inner walls of micro-holes, repair surface micro-defects, and enhance inner wall precision. As a modern alternative to traditional abrasive flow processes, this technology significantly improves processing quality, boosts efficiency, and lowers per-unit processing costs.

End face super polishing machine

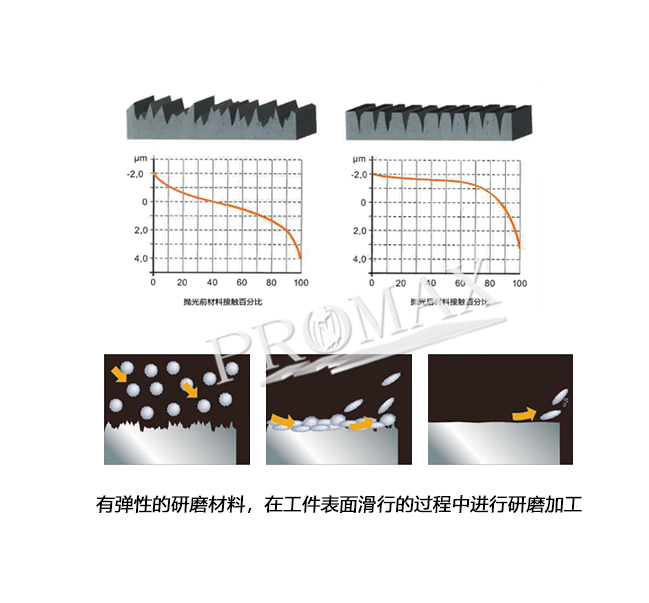

This model employs nano polishing technology to enhance surface roughness and improve the effective bonding area of mechanical parts. Through micro-amplitude, high-frequency, and flexible contact between the polishing tape and part surfaces, it selectively removes high points on the micro surface without altering the overall physical dimensions. It is ideal for improving the wear resistance of sliding friction surfaces and offers flexibility in selecting polishing materials to achieve user-specific surface quality parameters, including Ra, Rz, Rk, and Rpk.

This model utilizes nano polishing technology to enhance surface roughness and improve the effective bonding area of mechanical parts. By employing micro-amplitude, high-frequency, and flexible contact between the polishing tape and part surfaces, it selectively removes high points on the micro surface without altering the overall dimensions of the part. This technology is ideal for improving the wear resistance of sliding friction surfaces. Customizable polishing materials allow users to achieve desired surface quality parameters, such as Ra, Rz, Rk, and Rpk.

Wet flow rate deburring machine polishing equipment

This model features nano polishing technology, designed to enhance the surface roughness and effective bonding area of mechanical components. By employing micro-amplitude, high-frequency, and flexible contact between the polishing tape and part surfaces, it selectively removes high points on the micro surface without altering the overall dimensions of the part. This technology is ideal for improving the wear resistance of sliding friction surfaces and allows for customized polishing materials to achieve specific surface quality parameters, such as Ra, Rz, Rk, and Rpk.

Piston deburring and polishing equipment

This equipment is designed for deburring and polishing the inner and outer surfaces of various parts, including gears, short shafts, and discs. These parts often have multiple burrs that are challenging to remove using conventional methods. The machine employs flow wet abrasive high-speed motion to selectively remove burrs and utilizes flow rate polishing and pulse technology for efficient, versatile surface finishing. The deburring power head can operate across up to 10 stations simultaneously, with each station independently controlled to support high-efficiency production modes like precision punching. Users can choose between manual loading/unloading or robot-assisted automation based on their requirements.

Piston ring deburring and polishing equipment,Deburring of piston rings

This equipment is specifically designed for deburring and polishing the inner and outer surfaces of various components, such as gears, short shafts, and discs. These parts often present multiple burrs that are difficult to remove using conventional methods. The machine employs flow wet abrasive high-speed motion to selectively remove burrs and utilizes flow rate polishing and pulse technology for efficient and versatile surface finishing. To enhance productivity, the deburring power head can operate across up to 10 stations simultaneously, with each station independently controlled, catering to high-efficiency production modes like precision punching. Users can opt for manual loading/unloading or robotic automation, depending on their needs.

Crankshaft deburring and polishing equipment,Deburring of crankshaft

This model utilizes nano polishing technology, designed to enhance the surface quality of crankshafts by removing high points on the micro surface through micro amplitude, high-frequency, and flexible contact between the polishing tape and the part. This process improves surface roughness and increases the effective bonding area of mechanical components. The system is ideal for enhancing wear resistance on sliding friction surfaces. By selecting various polishing materials, users can achieve precise surface quality targets, including parameters such as Ra, Rz, Rk, and Rpk.

Camshaft deburring and polishing equipment

This model adopts nano polishing technology, which removes high points on the micro surface through micro amplitude, high-frequency, and flexible contact between the polishing tape and the surface of the parts, thereby achieving the effect of improving the surface roughness and effective bonding area of mechanical parts. This product can be widely used to improve the wear resistance of sliding friction surfaces. Different polishing materials can be selected to obtain the surface quality required by users for surface parameters such as Ra, Rz, Rk, Rpk, etc.

Cross hole deburring and polishing equipment

This model adopts nano polishing technology, which removes high points on the micro surface through micro amplitude, high-frequency, and flexible contact between the polishing tape and the surface of the parts, thereby achieving the effect of improving the surface roughness and effective bonding area of mechanical parts. This product can be widely used to improve the wear resistance of sliding friction surfaces. Different polishing materials can be selected to obtain the surface quality required by users for surface parameters such as Ra, Rz, Rk, Rpk, etc.

Cylinder body deburring and polishing equipment

This model adopts nano polishing technology, which removes high points on the micro surface through micro amplitude, high-frequency, and flexible contact between the polishing tape and the surface of the parts, thereby achieving the effect of improving the surface roughness and effective bonding area of mechanical parts. This product can be widely used to improve the wear resistance of sliding friction surfaces. Different polishing materials can be selected to obtain the surface quality required by users for surface parameters such as Ra, Rz, Rk, Rpk, etc.