Focus on metal deburring and surface treatment solutions

■ Equipment Introduction

This model utilizes nano polishing technology to enhance surface roughness and improve the effective bonding area of mechanical parts. By employing micro-amplitude, high-frequency, and flexible contact between the polishing tape and part surfaces, it selectively removes high points on the micro surface without altering the overall dimensions of the part. This technology is ideal for improving the wear resistance of sliding friction surfaces. Customizable polishing materials allow users to achieve desired surface quality parameters, such as Ra, Rz, Rk, and Rpk.

■ Advantages

- Advanced Nano Technology: Processes only the high points of the micro surface, preserving the original dimensions at a precision level of 0.01mm while linearly enhancing surface roughness. This eliminates the drawbacks of traditional polishing methods.

- Reliable and Stable: Built with mature manufacturing technology, ensuring precise and consistent performance.

- German Engineering: Incorporates European-made high-frequency vibration components for long-lasting reliability.

- Cost-Effective: Provides competitive pricing as an alternative to imported equipment.

- Modular Design: Simplifies operation and maintenance, ensuring user convenience.

This equipment offers cutting-edge, reliable, and efficient solutions for nano polishing, particularly suited to applications demanding high surface precision and durability.

■ Technical parameters

| Index | Parameter |

| Number Of Super Polishing Power Head | 1set or 2 set |

| WidthOf Polishing Belt | 10/20/100 mm |

|

Vibration Freqency Of Polishing Head |

100-2000time/min |

| Vibration Amplitude Of Polishing Head | 5 mm |

| Feeding Speed Of Polishing Belt | 1-20mm/min |

| Applicable Size and Shape Of WorkPiece | Customizable |

| The Shape Of Processed Surface | Cylindrical Surface Or Plane |

|

Polishing Blind Spot Width At Step |

<1.5mm |

|

Max Weight Of Workpiece |

5 Kg |

| Working Temperature | 0℃-55℃ |

| Power Supply Voltage | 380±10%V |

| Power Supply Frequency | 50 Hz |

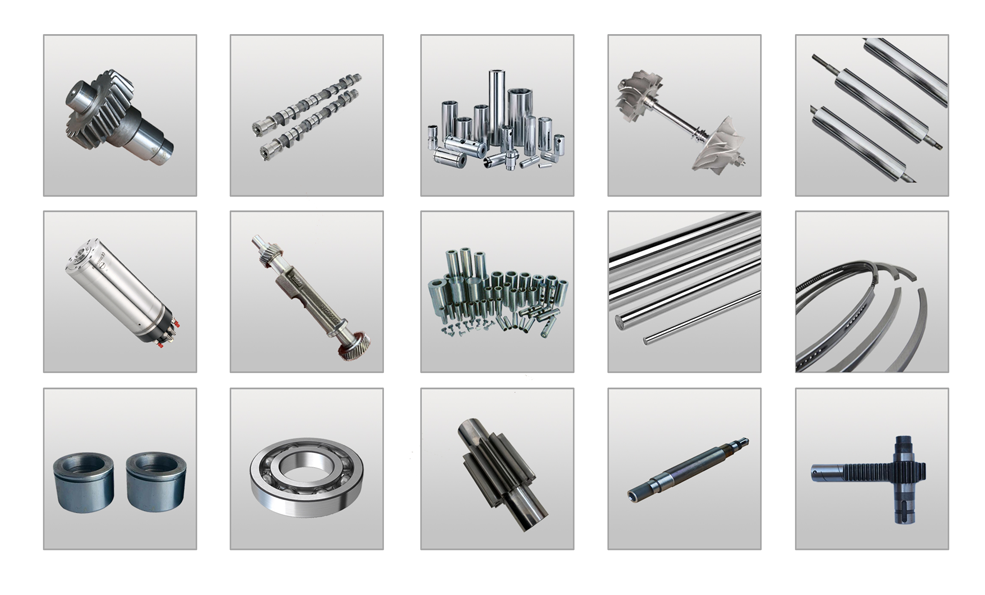

■ Suitable for processing parts

Keywords: OD super polishing machine

OD super polishing machine

Classification

Contact Information

Mobile: +86-18621973890

E-mail: info@deburringchina.com

B-416, No. 8 Hangyi Road, Fengxian District, Shanghai.

377 Laodong East Road, Tianning District, Changzhou City, Jiangsu Province.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Request Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!