Focus on metal deburring and surface treatment solutions

In the world of automotive and mechanical engineering, the deburring of piston rings is a crucial process that significantly impacts engine performance.Piston rings play a vital role in the internal combustion engine. They are responsible for sealing the combustion chamber, controlling oil consumption, and transferring heat. However, during the manufacturing process, burrs can form on the edges of piston rings. These burrs, if left unaddressed, can lead to a host of problems.

The deburring of piston rings is a highly specialized process. It involves the removal of these unwanted protrusions and rough edges with utmost precision. Advanced machinery and techniques are employed to ensure that the deburring is done without causing any damage to the delicate surface of the piston ring.

One of the key benefits of precise deburring is improved engine efficiency. Burrs can disrupt the smooth movement of the piston rings within the cylinder, leading to increased friction. By eliminating these burrs, the piston rings can move more freely, reducing friction and thus enhancing the overall efficiency of the engine. This can result in better fuel economy and reduced emissions, which are two critical factors in today's automotive industry.

In addition to efficiency, deburring also contributes to the durability of piston rings. Burrs can act as stress concentrators, making the piston rings more prone to wear and tear. When these are removed, the piston rings are more likely to withstand the harsh operating conditions within the engine, such as high temperatures and pressures. This extends the lifespan of the piston rings and reduces the need for frequent replacements, saving both time and cost for vehicle owners and manufacturers alike.

Manufacturers are constantly investing in research and development to improve the deburring process. New technologies, such as laser deburring, are being explored. Laser deburring offers a high - precision, non - contact method of removing burrs, which is especially useful for the intricate shapes and surfaces of piston rings. It can target burrs with extreme accuracy, leaving the surrounding area untouched.

Quality control also plays a major role in the deburring of piston rings. Stringent inspection procedures are in place to ensure that every piston ring that leaves the production line is free from burrs. This involves the use of high - magnification inspection tools and techniques to detect even the smallest of burrs that could potentially affect performance.

As the automotive industry continues to evolve and demand higher - performing engines, the deburring of piston rings will remain an essential part of the manufacturing process. It is a process that not only ensures the smooth operation of engines but also contributes to the overall reliability and environmental - friendliness of vehicles.

■ Equipment Introduction

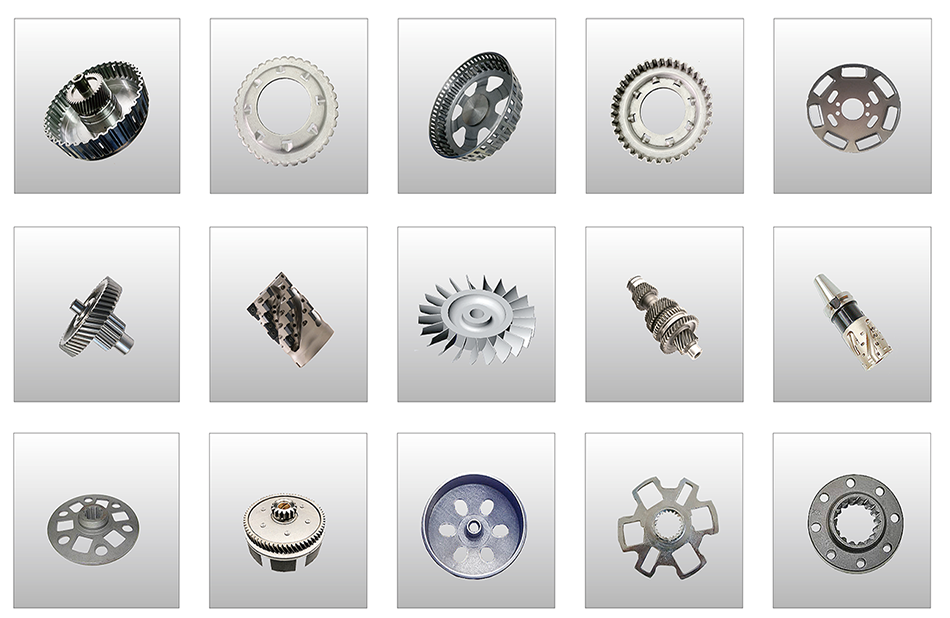

This equipment is specifically designed for deburring and polishing the inner and outer surfaces of various components, such as gears, short shafts, and discs. These parts often present multiple burrs that are difficult to remove using conventional methods. The machine employs flow wet abrasive high-speed motion to selectively remove burrs and utilizes flow rate polishing and pulse technology for efficient and versatile surface finishing. To enhance productivity, the deburring power head can operate across up to 10 stations simultaneously, with each station independently controlled, catering to high-efficiency production modes like precision punching. Users can opt for manual loading/unloading or robotic automation, depending on their needs.

■ Advantages

- Innovative Technology: Incorporates advanced flow rate polishing and pulse technology for precise and effective deburring.

- Efficient Surface Treatment: Combines high-speed abrasive rotation with part self-rotation, delivering micro-grinding and polishing.

- Wide Applicability: Supports a broad range of parts without the need for specialized fixtures.

- High Automation: Fully monitored processing with optional robotic integration for automation.

- Cost-Effective Solution: Offers performance comparable to imported systems at a significantly lower cost.

This equipment delivers a reliable and efficient solution for handling challenging deburring and polishing tasks, ideal for high-precision and high-efficiency manufacturing environments.

■ Technical parameters

| Index | Parameter |

| Dimensions | 5600mm×4500mm×2500mm |

| Diameterofabrasive barrel | φ2500 mm |

|

Workpiece Diameter |

φ200 mm |

| Workpiece Length | 200 mm |

| Maximum Weigth Of Workpiece | 4 Kg |

| Total Power | 100KW |

| Swing Angle | ±30℃ |

|

Power SupplyVoltage |

380±10%V |

|

Power Supply Frequenc |

50 Hz |

| Working Temperature | 0℃~55℃ |

■ Suitable for processing parts

Keywords: Piston ring deburring and polishing equipment,Deburring of piston rings

Piston ring deburring and polishing equipment,Deburring of piston rings

Classification

Contact Information

Mobile: +86-18621973890

E-mail: info@deburringchina.com

B-416, No. 8 Hangyi Road, Fengxian District, Shanghai.

377 Laodong East Road, Tianning District, Changzhou City, Jiangsu Province.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Request Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!