■ Equipment Introduction

This equipment is designed for single-sided or double-sided deburring of parts with sharp edge burrs formed during fine blanking, milling, or grinding processes. It employs a multi-process wet deburring system with independently controlled multi-moving heads. The power heads, featuring abrasive belt or multi-disk brush designs, are servo-lift controlled, ensuring precise removal of burrs and the formation of uniform rounded edges. Equipped with self-compensation capabilities, the machine supports unmanned operation and is ideal for deburring larger parts.

■ Equipment Features

- Enhanced Stability and Rigidity: Transition from welded assemblies to integral cast iron parts significantly improves stability, rigidity, and accuracy while preventing long-term deformation.

- Optimized Gearbox Design: Upgraded to cast aluminum parts, improving heat dissipation, reducing noise and vibration. The reverse rotation feature saves 30% on consumables and ensures consistent fillet and surface roughness.

- Precise Lifting Mechanism: Driven by an upper silver wire rod and Mitsubishi servo electric cylinder, ensuring 0.01mm accuracy for uniform brushing and reduced wear.

- Efficient Cooling Water Recovery: Sloped water tray design for improved cooling water collection and easy cleaning.

- Dry-Wet Area Separation: Isolated with an organ cover, featuring upper blowers and lower exhaust to manage mist and maintain a clean, dry workspace.

- Improved Aesthetics: Redesigned with arc-shaped structures for better appearance and optimized layout.

- Brush Wear Compensation: Automatic brush feed compensation to maintain consistent performance and support automation.

- Wide Conveyor Belt: 400mm belt width accommodates multiple rows of small parts for simultaneous processing.

- Integrated Demagnetization: Low-voltage, energy-efficient demagnetizer reduces residual magnetism to less than 3 Gauss.

■ Advantages

- Advanced Deburring: Efficiently removes flanging and hole burrs while reducing consumable loss by 30%.

- High Precision: Maintains fillet size, preserves shape and position tolerances, and allows adjustment of surface roughness.

- High Production Efficiency: Matches the rhythm of high-speed fine blanking machines.

- Durable Conveyor Belt: Supports up to 9mm thickness, with grooved designs for reliability and easy replacement.

- Effective Demagnetization: Residual magnetism reduced to less than 2 Gauss with energy-saving, low-heat technology.

- Double-Sided Deburring: Compatible with mature turning mechanisms for comprehensive deburring solutions.

This equipment delivers reliable, efficient, and precise deburring performance while optimizing operational costs and productivity.

■ Technical parameters

| Index | Parameter |

| Dimensions | 3200mm×1200mm×2100mm |

| Working Enviroment | 0℃-55℃ |

| Power Supply Voltage | 380±10%V |

| Power Supply Frequency | 50Hz |

| Total Power | 30Kw |

| Conveyor Speed | 1m/min-6m/min |

| Revolution Speed | 50rpm-200rpm |

| Rotation Speed | 800rpm-1600rpm |

| Workpiece Max Width | 350mm |

| Workpiece Max Thickness | 100mm |

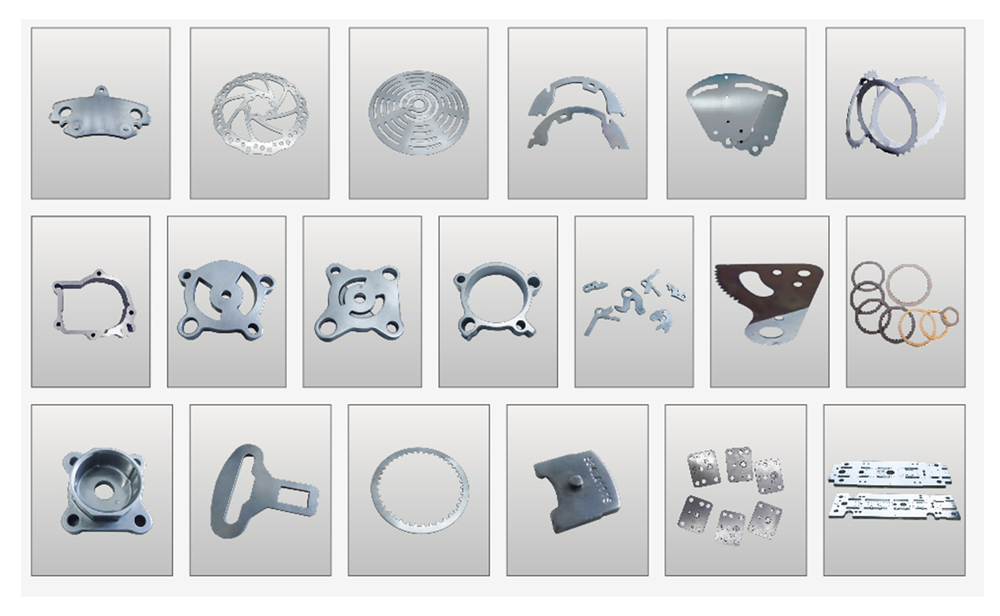

■ Suitable for processing parts

Keywords: Column type PT400 with external conveyor deburring machine

Column type PT400 with external conveyor deburring machine

Classification