■ Equipment Introduction

This device features pulse flow polishing technology, enabling advanced surface treatment of workpieces by combining circulating abrasives with rotating workpieces. It integrates multiple processes, such as deburring, smoothing, and polishing, into a single operation. This targeted approach ensures excellent surface quality for challenging flat and concave surfaces. The machine is versatile and applicable across industries with high surface treatment requirements.

■ Advantages

- World-Class Processing Speed: Delivers fast and efficient surface finishing.

- Enhanced Surface Quality: Reduces roughness from Ra 0.4 to 0.1 and Rpk 0.2 to 0.1 within minutes.

- Precision Control: Material removal is managed with μm-level accuracy.

- High Automation: Monitors the entire process for consistent and reliable results.

- German-Quality Engineering: Cost-effective solution with performance comparable to imported systems.

This equipment provides a cutting-edge solution for achieving superior surface treatment, meeting the most demanding industry standards.

■ Technical parameters

| Index | Parameter |

| Dimensions | 3155mm×1516mm×2694mm |

| Cylinder size | 1050mm×400mm |

|

Workpiece Length |

200 mm |

| Workpiece Diamter | 3-20 mm |

| Maximum Weight of workpiece | 4 Kg |

| Total Power | 20 Kw |

| Swing Angle | ±30° |

|

Power Supply Voltage |

380 V |

|

Power Supply Frequency |

50 Hz |

| Working Environment | 0℃~55°℃ |

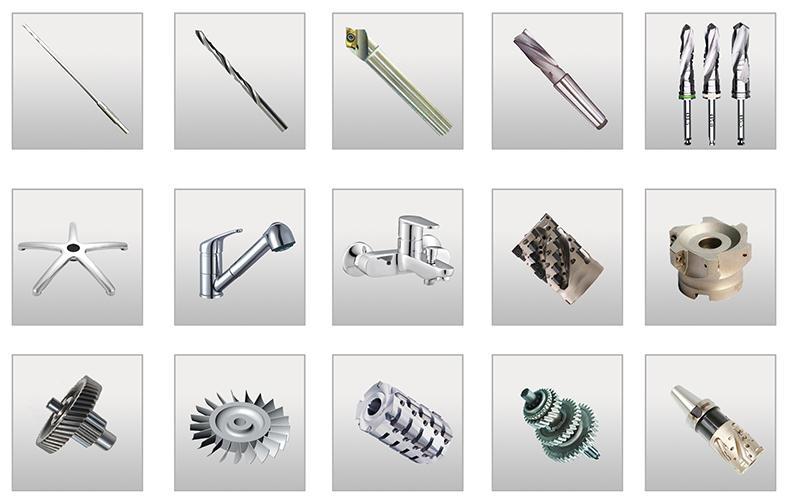

■ Suitable for processing parts

Keywords: 3D polishing machine, Irregular part polishing machine, Flow rate polishing machine

3D polishing machine, Irregular part polishing machine, Flow rate polishing machine

Classification