■ Equipment Introduction

This equipment is designed for single-sided and double-sided deburring of parts with sharp edges created by precision punching, milling, or grinding processes. It features a multi-process, multi-head wet deburring system, with independently controlled heads working simultaneously. The power heads use a sanding belt or multi-disc brush design, supported by servo-controlled lifting, to uniformly remove burrs, create consistent rounded corners, and enable unmanned operation. It is particularly suitable for deburring large parts.

■ Equipment Features

- Enhanced Stability and Rigidity: Transition to integral cast iron parts for the base and power head bracket improves stability, rigidity, and accuracy, avoiding deformation over long-term use.

- Upgraded Gearbox: Cast aluminum casing enhances heat dissipation, reduces noise and vibration, and the one-out-four configuration (with forward and reverse rotation) saves 30% on consumables while maintaining consistent surface roughness and rounded corners.

- Precision Lifting Mechanism: Mitsubishi servo cylinder and upper silver screw control the lifting within 0.01mm, ensuring consistent brush wear and burr removal.

- Cooling Water Recycling: Sloped water tray design facilitates efficient recycling and cleaning of cooling water.

- Dry-Wet Area Separation: Fully isolated by an accordion cover, with upper air blowing and lower air extraction to manage mist and maintain cleanliness.

- Improved Design: Circular arc appearance enhances aesthetics and structural efficiency.

- Self-Cleaning and Brush Compensation: Automatic cleaning and wear compensation ensure continuous performance and integration with automated systems.

- Wide Conveyor Belt: 400mm belt width increases processing capacity, accommodating multiple rows of smaller parts.

- Integrated Demagnetization: Proprietary low-voltage demagnetizer reduces residual magnetism to below 3 Gauss, with low power consumption and heat generation.

■ Advantages

- Advanced Technology: Effectively removes burrs from edges and holes with 30% lower consumables usage.

- High Precision: Maintains shape and position tolerances, with adjustable rounded corners and surface roughness.

- Fast Production: Matches the pace of high-speed precision punching machines.

- Durable Conveyor System: Supports up to 9mm thickness, with easy replacement and reliable operation.

- Efficient Demagnetization: Residual magnetism below 2 Gauss, ensuring consistent part quality.

- Double-Sided Deburring: Equipped with multiple flipping mechanisms for efficient processing.

This equipment provides a robust, efficient, and precise solution for automated deburring of high-precision components.

■ Technical parameters

| Index | Parameter |

| Dimensions |

3200mm×1200mm×2100mm |

| Working Environment |

0℃~55℃ |

|

Power Supply Voltage |

380±10%V |

| Power Supply Frequency | 50 Hz |

| Total Power | 30 Kw |

| Conveyor Speed | 1m/min-6m/min |

| Revolution Speed | 50rpm-200rpm |

| Rotation Speed | 800rpm-1600rpm |

| Workpiece Max Width | 350mm |

| Workpiece Max Thickness | 100mm |

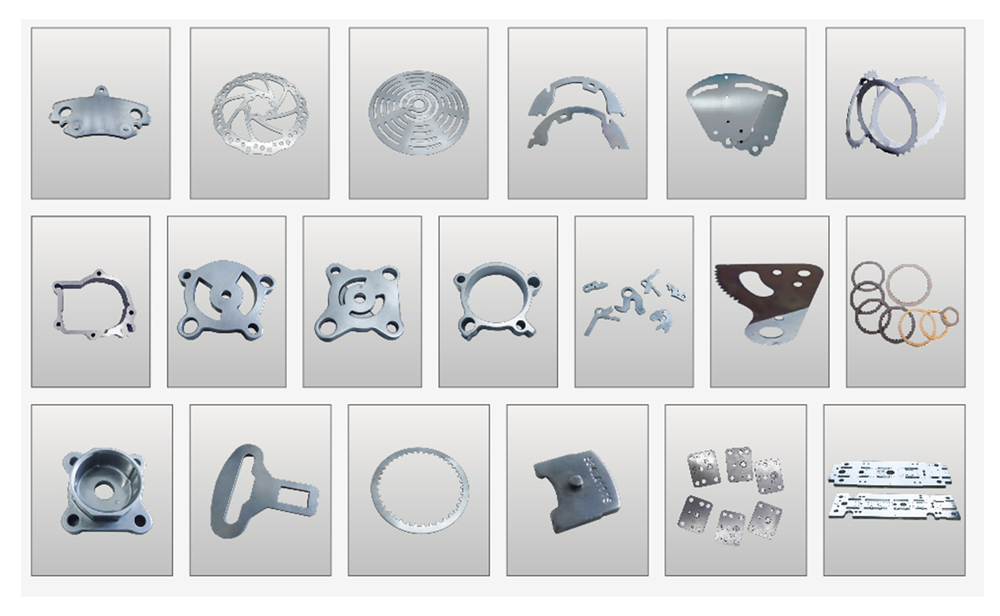

■ Suitable for processing parts

Keywords: Rotor deburring equipment

Rotor deburring equipment

Classification