■ Equipment Introduction

This equipment is designed for double-sided automatic deburring of flat parts, utilizing a wet deburring process with automatic flipping. Multiple power heads operate simultaneously, employing a multi-disc brush with rotational composite motion and servo lifting control. It ensures uniform removal of burrs across flat surfaces, forms consistent rounded corners, and features automatic compensation for unmanned operation. Integrated with upstream automation, the equipment effectively removes burrs from processes like double-sided milling and grinding with stability and efficiency.

■ Advantages

- Advanced Technology: Efficiently removes residual filamentous burrs from small hole openings, achieving high deburring efficiency with 30% reduced consumable consumption.

- High Precision: Controls the size of rounded corners without altering the shape or position tolerances of the deburring plane.

- Fast Production: High efficiency with a production cycle time of up to 1 second per part.

- Durable Conveyor System: Reliable, long-lasting drive system that is easy to replace.

- Effective Demagnetization: Low-power equipment achieves a residual magnetism of less than 2 Gauss.

- Automatic Demagnetization and Flipping: Enhances automation and operational efficiency.

This system provides a reliable, precise, and cost-effective solution for high-speed, automated deburring of flat components.

■ Technical parameters

| Index | Parameter |

| Dimensions |

3200mm×1200mm×2617mm |

| Working Environment |

0℃~55℃ |

|

Power Supply Voltage |

380±10%V |

| Power Supply Frequency | 50 Hz |

| Total Power | 15Kw |

| Conveyor Speed | 1m/min-6m/min |

| Revolution Speed | 50rpm-200rpm |

| Rotation Speed | 800rpm-1600rpm |

| Workpiece Max Width | 140mm |

| Workpiece Max Thickness | 100mm |

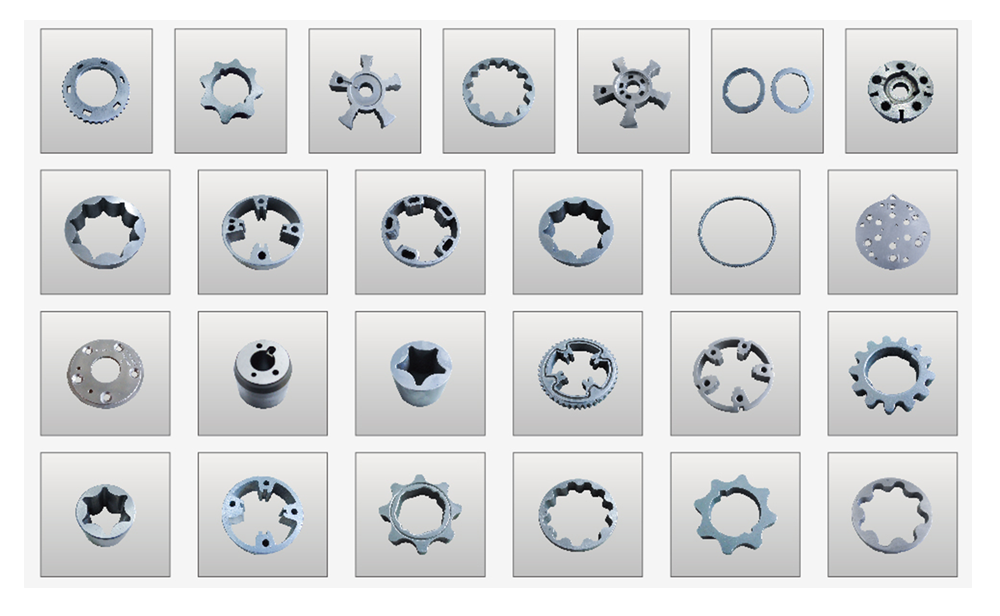

■ Suitable for processing parts

Keywords: Column type PT140 with flip deburring machine

Column type PT140 with flip deburring machine

Classification