■ Equipment Introduction

This specialized particle polishing machine offers nanoscale surface treatment for workpieces. Powered by compressed air, it generates a high-speed jet to spray elastic abrasive materials onto workpiece surfaces. This process subtly enhances surface cleanliness and roughness. With its ultra-fine abrasive particles, the machine can process complex surfaces, including narrow grooves, blind holes, and edges, and can handle components made from various materials by using tailored abrasives. It is widely applied in fields such as micro-hole deburring, mold polishing, tool passivation, and roughness improvement of components.

■ Advantages

- Innovative Technology: Introduces a revolutionary processing method for precision applications.

- High Accuracy: Maintains part dimensional tolerances while delivering consistent surface finishes.

- Dust-Free Processing: Dry operation minimizes dust generation and supports clean production environments.

- Cost Efficiency: Durable abrasives and optional abrasive regeneration systems significantly reduce operational costs.

- Automation Capability: Optional automatic loading and unloading systems enable fully automated production.

This equipment delivers precise, efficient, and adaptable polishing solutions, ideal for high-precision industries requiring enhanced surface treatments.

■ Technical parameters

| Index | Parameter |

| Dimensions | 3000mm×1665mm×1782mm |

| Airbrush | 1~2 PC |

|

Airbnush stroke |

0~400 mm |

| Number of cuting tools | 1~20 PC |

| Air Pump pressure | 0.8~1.0 Mpa |

|

Revolution Speed |

Adjustable |

| RotationSpeed | Adjustable |

|

Working Environment |

0℃~55℃ |

|

Power Supply Voltage |

380±10%V |

| Power Supply Frequency | 50 Hz |

| Total Supply Frequency | 10 Kw |

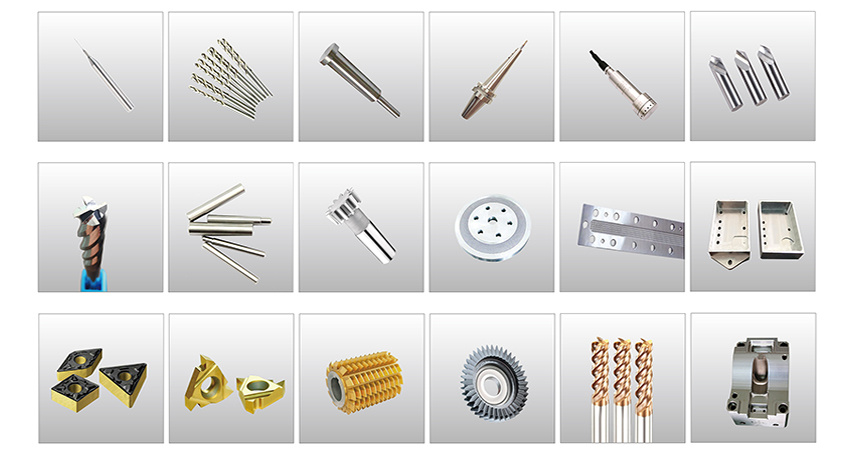

■ Suitable for processing parts

Keywords: Particle polishing machine

Particle polishing machine

Classification