■ Equipment Introduction

This machine is specifically designed for high-speed polishing of micro-holes smaller than 0.5 millimeters. It utilizes a liquid work mechanism to efficiently polish the inner walls of micro-holes, repair surface micro-defects, and enhance inner wall precision. As a modern alternative to traditional abrasive flow processes, this technology significantly improves processing quality, boosts efficiency, and lowers per-unit processing costs.

■ Advantages

- High Efficiency: Polishing speed is 5 times faster than traditional methods.

- Cost-Effective: Uses aqueous abrasives, which are low-cost and easy to clean off parts after polishing.

- Comprehensive Polishing: Achieves full-channel polishing, reaching every corner requiring precision treatment.

- Adjustable Intensity: Polishing intensity and effects can be precisely controlled and tailored.

- User-Friendly: Simple fixtures allow for easy clamping and operation.

This machine delivers advanced, efficient, and cost-effective solutions for precision micro-hole polishing, meeting the demands of high-quality industrial applications.

■ Technical parameters

| Index | Parameter |

| Dimensions |

4500mm×2000mm×2150m |

| Working Environment |

0℃~55℃ |

|

Power Supply Voltage |

380±10%V |

| Power Supply Frequency | 50 Hz |

| Total Supply Frequency | 25 Kw |

| Piece Width | Fixtures can Be Customized |

| Piece Thickness | Fixtures can Be Customized |

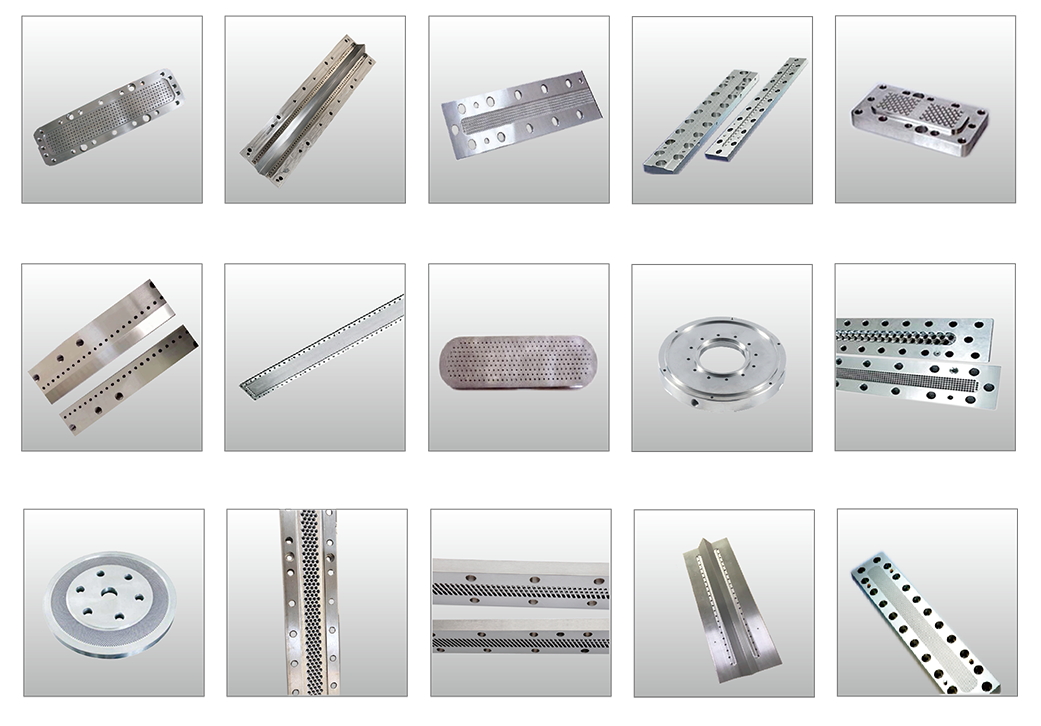

■ Suitable for processing parts

Keywords: Micro hole polishing machine

Micro hole polishing machine

This machine is specifically designed for high-speed polishing of micro-holes smaller than 0.5 millimeters. It utilizes a liquid work mechanism to efficiently polish the inner walls of micro-holes, repair surface micro-defects, and enhance inner wall precision. As a modern alternative to traditional abrasive flow processes, this technology significantly improves processing quality, boosts efficiency, and lowers per-unit processing costs.

Classification