■ Equipment Introduction

This equipment is designed for deburring and polishing the inner and outer surfaces of various parts, including gears, short shafts, and discs. These parts often have multiple burrs that are challenging to remove using conventional methods. The machine employs flow wet abrasive high-speed motion to selectively remove burrs and utilizes flow rate polishing and pulse technology for efficient, versatile surface finishing. The deburring power head can operate across up to 10 stations simultaneously, with each station independently controlled to support high-efficiency production modes like precision punching. Users can choose between manual loading/unloading or robot-assisted automation based on their requirements.

■ Advantages

- Innovative Technology: Features flow rate polishing and pulse technology for precise and efficient deburring.

- High-Speed Processing: Combines abrasive high-speed rotation with self-rotation of parts for micro-grinding surface treatment.

- Versatility: No need for specialized fixtures, accommodating a wide range of parts.

- Automation: Fully monitored processing with the option for robotic automation.

- Cost-Effective Alternative: Comparable to imported systems at a significantly lower cost.

This equipment provides a robust, efficient, and flexible solution for tackling complex deburring and polishing challenges in modern manufacturing.

■ Technical parameters

| Index | Parameter |

| Dimensions | 5600mm×4500mm×2500mm |

| Diameterofabrasive barrel | φ2500 mm |

|

Workpiece Diameter |

φ200 mm |

| Workpiece Length | 200 mm |

| Maximum Weigth Of Workpiece | 4 Kg |

| Total Power | 100KW |

| Swing Angle | ±30℃ |

|

Power SupplyVoltage |

380±10%V |

|

Power Supply Frequenc |

50 Hz |

| Working Temperature | 0℃~55℃ |

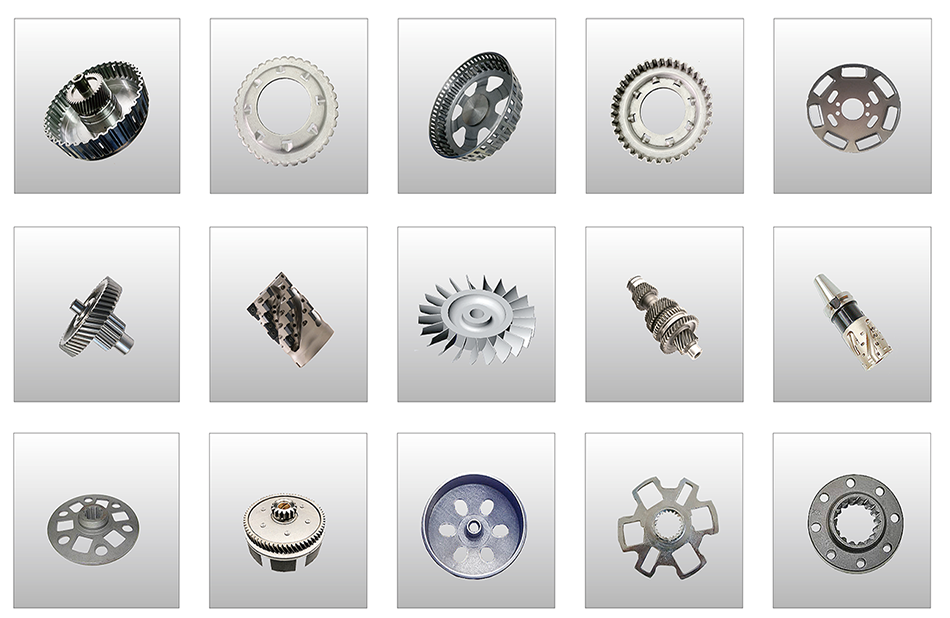

■ Suitable for processing parts

Keywords: Piston deburring and polishing equipment

Piston deburring and polishing equipment

Classification