■ Equipment Introduction

Equipment for removing single-sided sharp edges and burrs generated during the processing of valve plates, sheet metal parts, precision punched parts, and other materials such as stainless steel, copper, and aluminum. The equipment adopts negative pressure adsorption conveying method and can be designed with multiple processes and power heads integrated. During operation, multiple power heads are independently controlled and work simultaneously. The power heads are designed with sand belts or multiple Disc Brushes to serve the lifting control. It can uniformly and effectively remove burrs from multiple parts of the plane and form uniform rounded corners. The burrs are automatically compensated, achieving less manual operation. Equipment assembly line: 1 Two devices can form a production line, with automatic flipping in the middle to achieve simultaneous removal of burrs on both sides. 2. Equipped with automatic feeding function. 3. Equipped with a turning conveyor, the parts are transported back to the origin and automatically unloaded.

■ Advantages

● Advanced technology can effectively remove burrs on the edges and holes, with a high Deburring efficiency and a 30% reduction in consumables.

● High precision, can control the size of rounded corners without changing the tolerance of deburring plane shape and position, and can adjust the roughness of the plane according to needs.

● High production efficiency, production pace can be matched with high-speed precision punching machines.

● Vacuum negative pressure adsorption conveying and feeding (suitable for workpieces such as stainless steel plates, copper plates, aluminum plates, etc. that are not magnetically adsorbed).

■ Technical parameters

| Index | Parameter |

| Dimensions | 3200mm×1200mm×2617mm |

| Working Environment | 0℃~55℃ |

| Power Supply Voltage | 380±10%V |

| Power Supply Frequency | 50 Hz |

| Total Power | 18Kw |

| Conveyor Speed | 2m/min15m/min |

| Revolution Speed | 60rpm-120rpm |

| Rotation Speed | 800rpm-1600rpm |

| Workpiece Max Width | 350mm |

| Workpiece Max Thickness | 2mm-30mm |

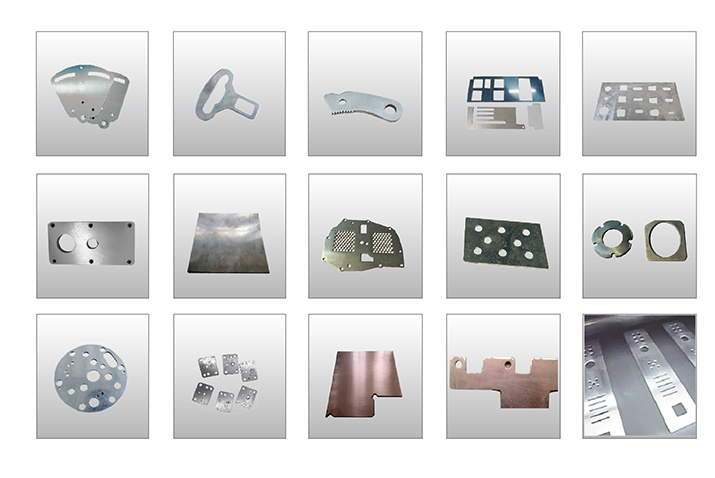

■ Suitable for processing parts

Keywords: Vacuum adsorption flat deburring machine

Vacuum adsorption flat deburring machine

Classification