■ Equipment Introduction

This equipment leverages advanced internal cavity grinding technology from the United States, utilizing spherical steel balls as abrasives. The abrasives, propelled by fluid motion, are pressed through machining surfaces or inner holes to perform grinding. This process is particularly effective for complex parts such as concave surfaces and curved holes that are inaccessible to conventional tools. It ensures safe and reliable internal cleaning, deburring, and polishing of castings, addressing defects and cleanliness issues in sharp edges, flow channels, air passages, and water chamber inner walls of intricate box parts.

■ Advantages

- Innovative Technology: High efficiency in cleaning, deburring, and polishing inner cavities of complex parts.

- Integrated Processing: Handles intricate components while meeting universal deburring and cleaning requirements.

- Cost-Effective Operation: Low operating costs, easy abrasive cleaning, and no residual risks.

- Robust Design: Earthquake-resistant construction, high-quality configuration, and reliable 24-hour continuous operation.

- Versatile Application: Advanced process design tailored for various part types.

- Comprehensive Expertise: Extensive knowledge in rheology, hydraulic grinding, and abrasive flow technology, providing optimal deburring and polishing solutions.

This cutting-edge equipment ensures precision, reliability, and efficiency, catering to the most challenging deburring and polishing tasks.

■ Technical parameters

| Index | Parameter |

| Dimensions | 2100mm×1900mm×2500mm |

| Gross Weight | 4000Kg(4400ibs) |

| Worktable Height | 1040mm |

| Processing Area (W×D) | 1200mm×760mm |

| Max Workpiece Weight | 200Kg |

| Abrasive | Steel Ball Or Abrasive Ball bead |

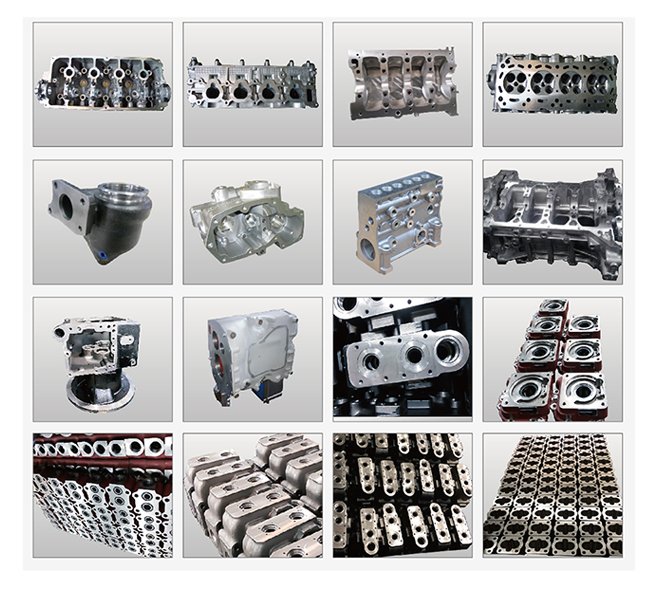

■ Suitable for processing parts

Keywords: Chamber deburring machine

Chamber deburring machine

Classification