■ Equipment Introduction

This equipment is designed for double-sided automatic deburring of flat parts. It utilizes wet deburring and automatic flipping, with multiple power heads operating simultaneously during the process. Key features include:

- Advanced Power Head Design: Multi-disc brush with revolution and rotational composite motion, controlled by servo lifting for precision.

- Effective Burr Removal: Uniformly removes burrs across flat surfaces while forming consistent rounded edges.

- Automatic Compensation: Ensures consistent performance and allows for unmanned operation.

- Seamless Integration: Connects with upstream automation processes for efficient and stable removal of burrs created by typical methods such as double-sided milling and grinding.

This innovative solution delivers reliable, high-quality deburring while enhancing productivity and reducing manual intervention.

■ Technical parameters

| Index | Parameter |

| Dimensions | 3200mm×1200mm×2100mm |

| Working Environment | 0℃~55℃ |

| Power Supply Voltage | 380±10%V |

| Power Supply Frequency | 50 Hz |

| Total Power | 15 Kw |

| Conveyor Speed | 1m/min-6m/min |

| Revolution Speed | 50rpm-200rpm |

| Rotation Speed | 800rpm-1600rpm |

| Workpiece Max Width | 140mm |

| Workpiece Max Thickness | 100mm |

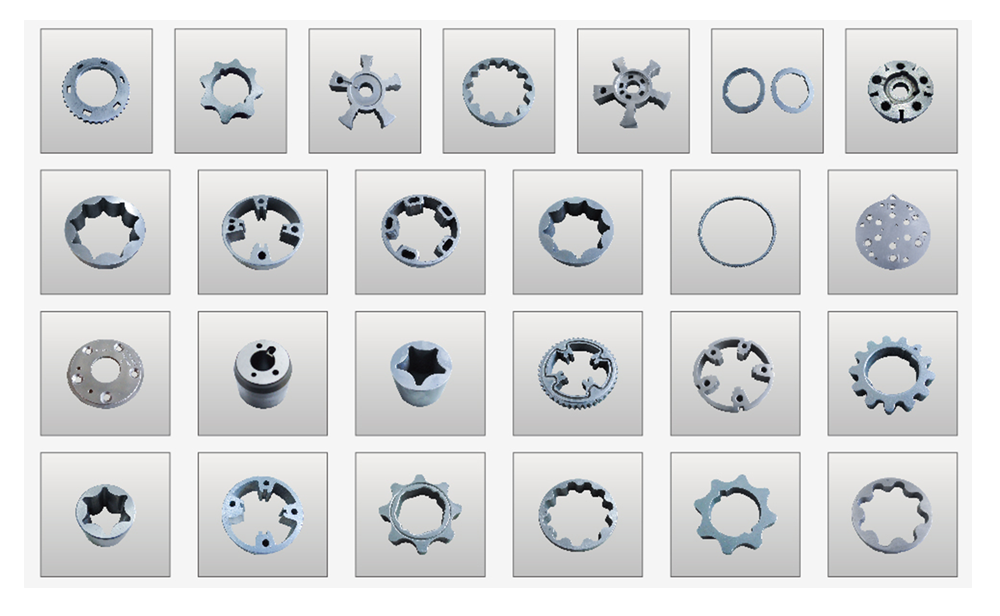

■ Suitable for processing parts

Keywords: PT140 Automatic flipping deburring machine

PT140 Automatic flipping deburring machine

This equipment is designed for double-sided automatic deburring of flat parts. It utilizes wet deburring and automatic flipping, with multiple power heads operating simultaneously during the process.

Classification