// ABOUT US

WHY CHOOSE PROMAX DEBURRING

Manufacturing Strength

From raw materials to shipment, nearly every production process undergoes rigorous quality testing to guarantee exceptional

Price Advantage

We offer a comprehensive pre-sales and after-sales service system, providing one-on-one support, installation, and technical assistance for complete peace of mind

Satisfaction Guarantee

Promax Group offers a comprehensive pre-sales and after-sales service system, ensuring a seamless 1-on-1 experience for every customer. We provide expert installation and technical support, guaranteeing complete satisfaction and peace of mind with our after-sales service.

// PRODUCTS

DEBURRING MACHINES

// PRODUCT CASES

Meet the special requirements of different users for deburring quality, efficiency, and other aspects

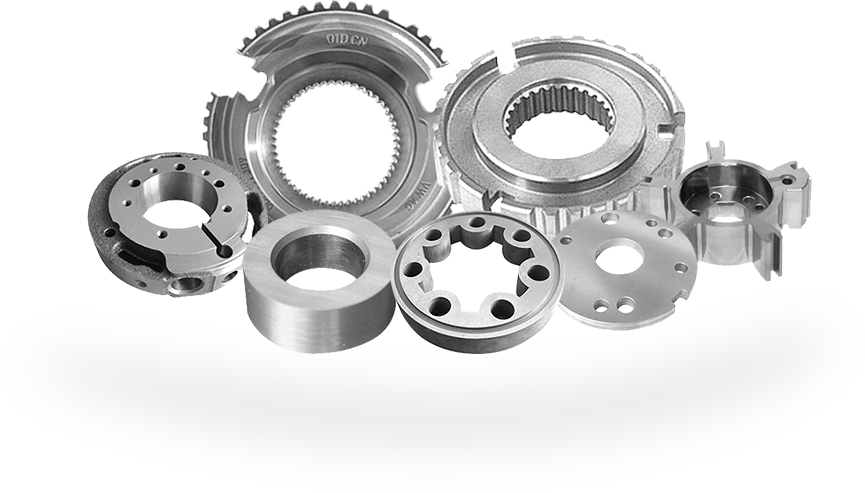

Typical applications include powertrain and components from major automakers such as General Motors, Dongfeng Motor, and SAIC Motor; Transmission assembly and components; New energy vehicle powertrain and components; Various hydraulic valve bodies; Air conditioning compressor components; Aircraft engine components, etc.

// OUR COMPANY

Focus on metal deburring and surface treatment solutions

Shanghai Promax Electromechanical Manufacturing Co., Ltd. was established in 2006, originating from Promax Engineering LLC in the United States. Based on the basic research of high-performance deburring technology, the company is a professional manufacturer of automatic deburring equipment that integrates research and development, manufacturing, sales, technical support, and after-sales service.

// OUR CUSTOMERS REVIEW

What say our customers

// BLOG

News & Blog