Focus on metal deburring and surface treatment solutions

In the ever - evolving landscape of manufacturing, a new star has emerged - the .The AI fully intelligent deburring automatic line is a game - changer in the field of precision manufacturing. This innovative system combines the power of artificial intelligence with advanced mechanical engineering to provide an unprecedented level of efficiency and accuracy in the deburring process.

At the heart of this automatic line is its AI - driven control system. The AI algorithms are designed to analyze the workpiece's geometry, surface roughness, and burr characteristics in real - time. Based on this analysis, the system can precisely adjust the deburring parameters, such as the speed and pressure of the deburring tools, to ensure optimal results for each individual piece. This adaptability is crucial, as different workpieces may have varying degrees of burr formation and surface requirements.

The fully intelligent nature of this line also extends to its self - learning capabilities. As it processes more and more workpieces, the AI system accumulates data and refines its algorithms, continuously improving its performance over time. This means that manufacturers can expect a consistently high - quality deburring output, with fewer defects and rework.

The deburring automatic line is equipped with a range of high - precision deburring tools. These tools are carefully selected and optimized to work in harmony with the AI - controlled system. They can effectively remove burrs from various materials, including metals, plastics, and composites, without causing any damage to the underlying surface.

One of the most significant advantages of this system is its high - speed operation. It can process workpieces at a much faster rate compared to traditional deburring methods. This not only increases productivity but also reduces the overall production cycle time, allowing manufacturers to meet tight deadlines and gain a competitive edge in the market.

In addition, the AI fully intelligent deburring automatic line offers enhanced safety features. With automated operation, the risk of human - error - related accidents is minimized. The system also has built - in safety sensors that can detect any abnormal conditions, such as tool breakage or workpiece misalignment, and immediately halt the operation to prevent further damage.

Furthermore, the system is designed to be highly customizable. Manufacturers can configure the line according to their specific production requirements, whether it is for small - batch, high - precision manufacturing or large - scale mass production.

As the manufacturing industry continues to strive for greater precision, efficiency, and quality, the AI fully intelligent deburring automatic line is set to become an indispensable tool. It represents a significant step forward in the automation of the deburring process, bringing with it a host of benefits that will transform the way manufacturers operate and enhance their competitiveness in the global marketplace.

■ Equipment Introduction

This equipment is designed for double-sided automatic deburring of flat parts. It utilizes wet deburring and automatic flipping, with multiple power heads operating simultaneously during the process. Key features include:

- Advanced Power Head Design: Multi-disc brush with revolution and rotational composite motion, controlled by servo lifting for precision.

- Effective Burr Removal: Uniformly removes burrs across flat surfaces while forming consistent rounded edges.

- Automatic Compensation: Ensures consistent performance and allows for unmanned operation.

- Seamless Integration: Connects with upstream automation processes for efficient and stable removal of burrs created by typical methods such as double-sided milling and grinding.

This innovative solution delivers reliable, high-quality deburring while enhancing productivity and reducing manual intervention.

■ Technical parameters

| Index | Parameter |

| Dimensions | 3200mm×1200mm×2100mm |

| Working Environment | 0℃~55℃ |

| Power Supply Voltage | 380±10%V |

| Power Supply Frequency | 50 Hz |

| Total Power | 15 Kw |

| Conveyor Speed | 1m/min-6m/min |

| Revolution Speed | 50rpm-200rpm |

| Rotation Speed | 800rpm-1600rpm |

| Workpiece Max Width | 140mm |

| Workpiece Max Thickness | 100mm |

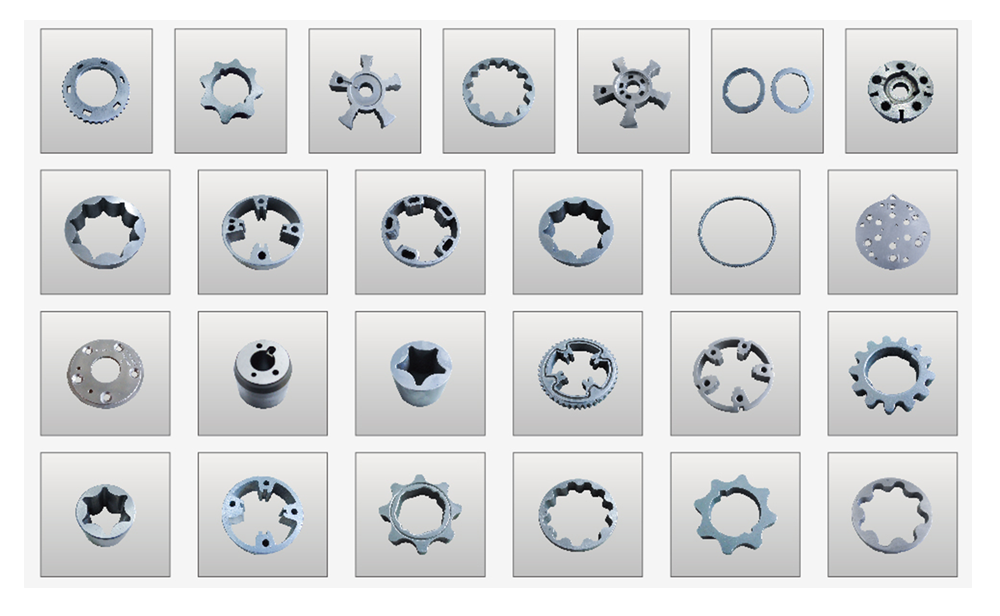

■ Suitable for processing parts

Keywords: PT140 Automatic flipping deburring machine,AI fully intelligent deburring automatic line

PT140 Automatic flipping deburring machine,AI fully intelligent deburring automatic line

Classification

Contact Information

Mobile: +86-18621973890

E-mail: info@deburringchina.com

B-416, No. 8 Hangyi Road, Fengxian District, Shanghai.

377 Laodong East Road, Tianning District, Changzhou City, Jiangsu Province.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Request Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!