Focus on metal deburring and surface treatment solutions

■ Equipment Introduction

This model is an economical configuration of a sheet metal Deburring machine. During use, the dual action head works, with the first action head removing burrs from the edge of the punched part and the second action head removing sharp edges and forming uniform rounded corners. The structure is simple, efficient, and easy to operate. On average, one part takes 2-3 seconds. As a standard model for mass production in our company, the cost-effectiveness is very high. Suitable for Deburring requirements of general stamping parts.

■ Advantages

● Good universality.

● Advanced technology, capable of effectively removing large burrs and burrs, with high deburring efficiency.

● Mature technology and high cost-effectiveness.

● Excellent manufacturing process and good stability.

● The demagnetization equipment has low power (less than one kilowatt) and good demagnetization effect.

■ Technical parameters

| Index | Parameter |

| Dimensions | 2820mm×1320mm×2450mm |

| Working Environment | 0℃~55℃ |

| Power Supply Voltage | 380±10%V |

| Power Supply Frequency | 50 Hz |

| Total Power | 13.5 Kw |

| Conveyor Speed | 1m/min-5m/min |

| Revolution Speed | 60rpm-120rpm |

| Rotation Speed | 800rpm-1600rpm |

| Workpiece Max Width | 370mm |

| Workpiece Max Thickness | 1-20mm |

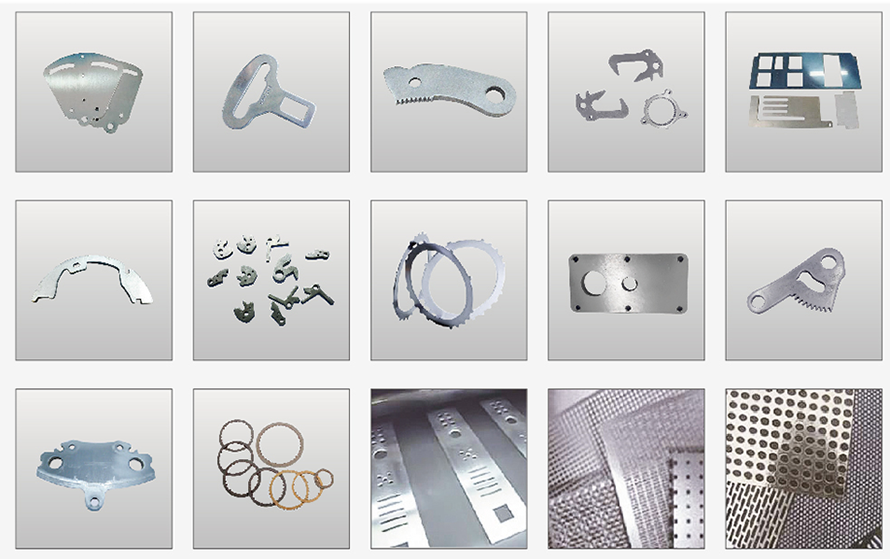

■ Suitable for processing parts

Keywords: Economic sheet metal deburring machine

Economic sheet metal deburring machine

Classification

Contact Information

Mobile: +86-18621973890

E-mail: info@deburringchina.com

B-416, No. 8 Hangyi Road, Fengxian District, Shanghai.

377 Laodong East Road, Tianning District, Changzhou City, Jiangsu Province.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Request Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!