Focus on metal deburring and surface treatment solutions

■ Equipment Introduction

This equipment is designed for single-sided and double-sided deburring of parts with sharp edges created by precision punching, milling, or grinding processes. It features a multi-process, multi-head wet deburring system, with independently controlled heads working simultaneously. The power heads use a sanding belt or multi-disc brush design, supported by servo-controlled lifting, to uniformly remove burrs, create consistent rounded corners, and enable unmanned operation. It is particularly suitable for deburring large parts.

■ Equipment Features

- Enhanced Stability and Rigidity: Transition to integral cast iron parts for the base and power head bracket improves stability, rigidity, and accuracy, avoiding deformation over long-term use.

- Upgraded Gearbox: Cast aluminum casing enhances heat dissipation, reduces noise and vibration, and the one-out-four configuration (with forward and reverse rotation) saves 30% on consumables while maintaining consistent surface roughness and rounded corners.

- Precision Lifting Mechanism: Mitsubishi servo cylinder and upper silver screw control the lifting within 0.01mm, ensuring consistent brush wear and burr removal.

- Cooling Water Recycling: Sloped water tray design facilitates efficient recycling and cleaning of cooling water.

- Dry-Wet Area Separation: Fully isolated by an accordion cover, with upper air blowing and lower air extraction to manage mist and maintain cleanliness.

- Improved Design: Circular arc appearance enhances aesthetics and structural efficiency.

- Self-Cleaning and Brush Compensation: Automatic cleaning and wear compensation ensure continuous performance and integration with automated systems.

- Wide Conveyor Belt: 400mm belt width increases processing capacity, accommodating multiple rows of smaller parts.

- Integrated Demagnetization: Proprietary low-voltage demagnetizer reduces residual magnetism to below 3 Gauss, with low power consumption and heat generation.

■ Advantages

- Advanced Technology: Effectively removes burrs from edges and holes with 30% lower consumables usage.

- High Precision: Maintains shape and position tolerances, with adjustable rounded corners and surface roughness.

- Fast Production: Matches the pace of high-speed precision punching machines.

- Durable Conveyor System: Supports up to 9mm thickness, with easy replacement and reliable operation.

- Efficient Demagnetization: Residual magnetism below 2 Gauss, ensuring consistent part quality.

- Double-Sided Deburring: Equipped with multiple flipping mechanisms for efficient processing.

This equipment provides a robust, efficient, and precise solution for automated deburring of high-precision components.

■ Technical parameters

| Index | Parameter |

| Dimensions |

3200mm×1200mm×2100mm |

| Working Environment |

0℃~55℃ |

|

Power Supply Voltage |

380±10%V |

| Power Supply Frequency | 50 Hz |

| Total Power | 30 Kw |

| Conveyor Speed | 1m/min-6m/min |

| Revolution Speed | 50rpm-200rpm |

| Rotation Speed | 800rpm-1600rpm |

| Workpiece Max Width | 350mm |

| Workpiece Max Thickness | 100mm |

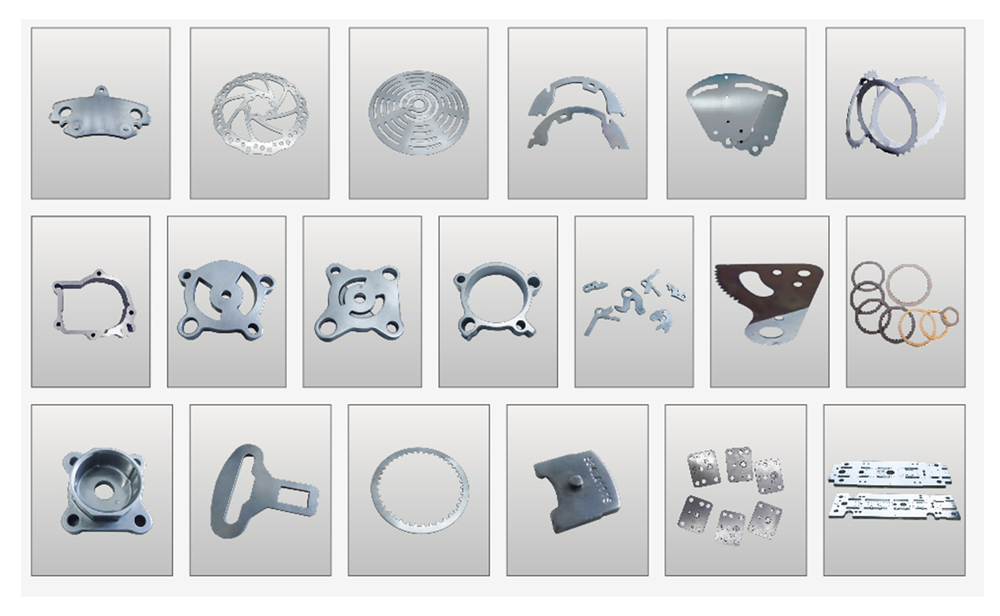

■ Suitable for processing parts

Keywords: Rotor deburring equipment

Rotor deburring equipment

Classification

Contact Information

Mobile: +86-18621973890

E-mail: info@deburringchina.com

B-416, No. 8 Hangyi Road, Fengxian District, Shanghai.

377 Laodong East Road, Tianning District, Changzhou City, Jiangsu Province.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Request Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!